Why Choose Omega

Discover why Omega stands out. Learn about our history, diverse applications, and key benefits. Use our savings calculator and explore our worldwide presence to see how Omega can meet your needs.

Connect with our teamEfficiency Redefined

Experience superior quality with Omega. Our advanced technology and durable products provide consistent results, enhancing productivity and reducing operational expenses.

Self-cleaning filtration system

No chemicals are used in the process.

On-site processing

Reduces CO2 emissions and trips to disposal sites.

Return up to 80% of the grease trap or septic tank content

Returned water has been purified at 99%

Increase productivity

2x to 4x more septic tank per truck 2x to 3x more grease trap per truck

Reduce maintenance cost

Up to 15,000 miles saved on the road annually.

Eco-Efficient solution

GHG emissions reduced by 47%

See How Much You Can Save With Omega On Your Operations

Use our savings calculator to see how an Omega truck can benefits your operations. Discover how investing in an Omega truck can lead to significant cost reductions and improved efficiency.

Daily Operational cost

Full Pump or Traditional System

Water Return Omega Technology

Savings per day

Full Pump or Traditional System

Based on a 10 wheel truck

4,000 US Gal. / debris

Water Return Omega Technology

Based on a 10 wheel truck

3,800 US Gal. / debris.

Savings per day

Full Pump or Traditional System

Collecting the whole tank content

1,000 US Gal./tank x 12 x $0.08/US Gal.

Water Return Omega Technology

Scum and sludge collecting only

300 US Gal./tank x 12 x $0.08/US Gal.

Savings per day

Full Pump or Traditional System

3 trips per 12 tanks

A 10 wheels traditional truck holds the contents of 4 septic tanks. For 12 tanks, it must go 3 times to disposal site. 50 miles x 3 trips x $1,50/miles.

Milage =

Water Return Omega Technology

1 trip per 12 tanks

A 10 wheels Omega truck holds the contents of 12 septic tanks. For 12 tanks, only one trip to disposal site is necessary. 50 miles x 1 trips x $1,50/miles

Milage =

Savings per day

Full Pump or Traditional System

Tank collecting

20 min/tank x 12hacker

Transportation to disposal site 1h (50 miles round trip) x 3 trips

Sludge disposal at the disposal site 20 min/trip x 3 trips

Total Time

Water Return Omega Technology

Tank collecting

25 min/tank x 12

Transportation to disposal site 1 hour (50 miles round trip) x 1 trip

Sludge disposal at the disposal site 20 min/trip x 1 trip

Total Time

Savings per day

Why Omega Stands Out

Trusted by leading companies worldwide, Omega is renowned for its certified excellence and innovative solutions. Our dedicated team of experts ensures top performance and reliability, making us the preferred choice in the industry.

Proven Productivity and Sustainability

The aim of this study was to investigate and quantify the advantages of the bluewater™ Recycler Truck, featuring the unique Juggler™ pumping and liquid-solid separating system. The primary benefits examined were increased productivity and a reduced carbon footprint. The Juggler™ technology significantly lowers CO2 emissions compared to conventional pumpers. For residential operations, it reduces carbon emissions by 49 to 54% (from 58.89 kg of CO2 per site for a conventional pumper to 30.14 or 26.85 kg of CO2 per site, depending on the workday length). For commercial operations, it achieves a 60% reduction (from 51.96 to 20.79 kg of CO2 per site).

Learn MoreRecycled Greywater in Grease Interceptors: A Viable Alternative

The purpose of this study was to compare the effectiveness of grease interceptors using recycled greywater versus those with full pump-out of waste material. The oil and grease concentration in the outlet wastewater of grease interceptors with recycled greywater, measured using EPA Method 1664, averaged over 30-day cycles, was comparable to that of interceptors with full pump-out of waste material. No significant differences in effluent FOG concentration were observed between the two treatment types at the tested sites during either phase.

Learn MoreThey trust us!

Leading industry players choose Omega for our unmatched reliability, innovative technology, and exceptional customer support. Our advanced solutions and dedicated team ensure optimal performance and efficiency, making us the preferred partner for top companies.

The Omega difference

Omega’s distinction lies in our superior customer service, our in-house engineering team, and extensive field training. We are dedicated to delivering unparalleled support, innovative technologies, and the expertise needed to excel in the industry.

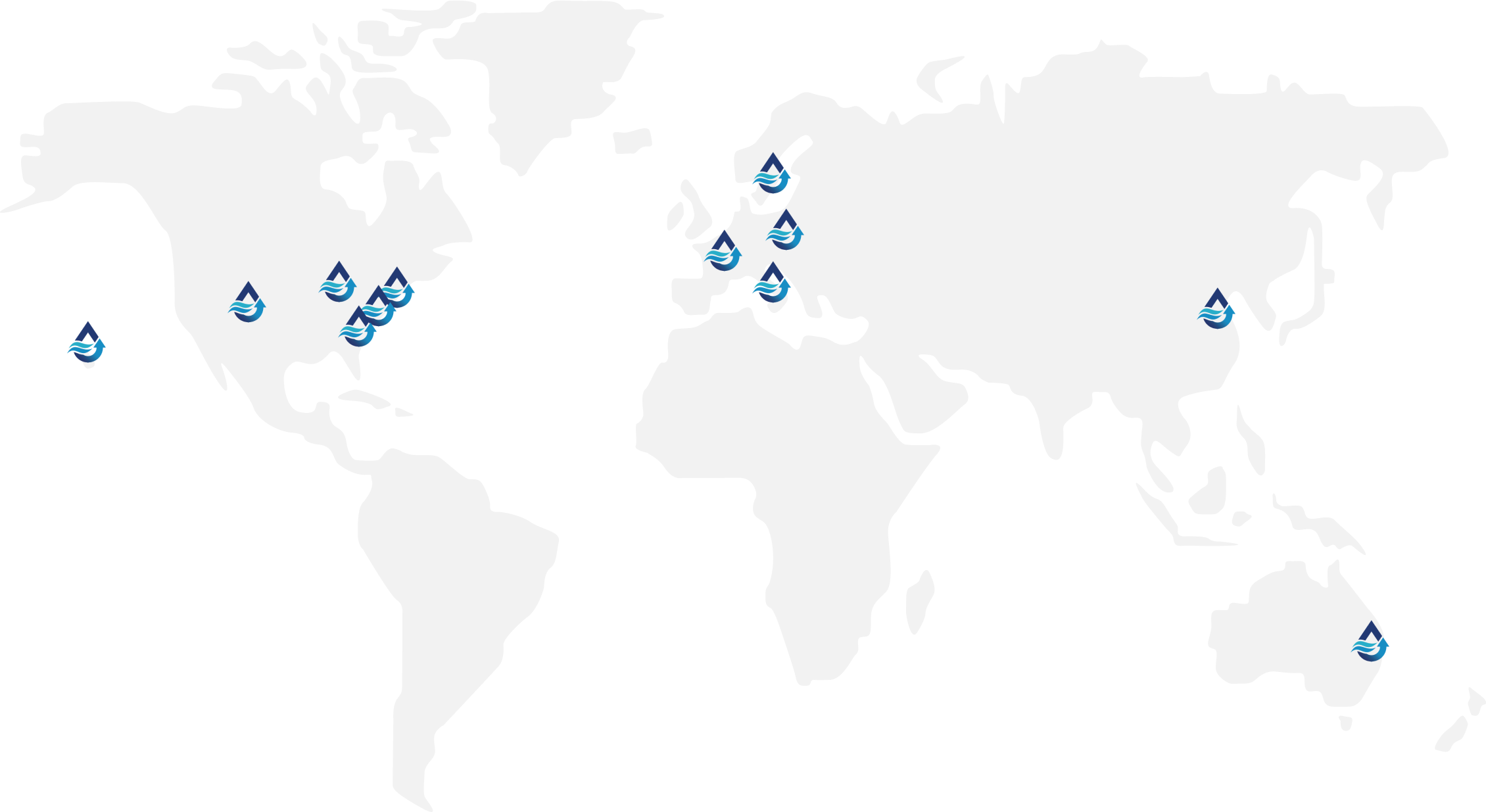

Omega Global Presence

Omega products are sold worldwide, ensuring our innovative solutions are available to customers across the globe. Experience the reliability and quality of Omega, no matter where you are.